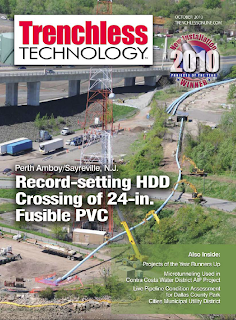

The 2010 Trenchless Technology Project of the Year for New Installation brought together everything that is exciting about a challenging project: teamwork, tough subsurface conditions, challenging logistics and drilling under water over a great distance that sets a new standard for pipe performance.

All of these elements successfully converged in New Jersey in spring 2010, resulting in a 5,365-ft HDD project that brought customers of the Middlesex Water Co. a new 24-in. fusible PVC water main that was able to be installed quickly, efficiently and perhaps, more importantly, cost-effectively. Project officials also note that this project set a world-record for distance using 24-in. FPVC.

The project took place in a largely urban area in central New Jersey in Perth Amboy and Sayreville. An overwhelming majority of the project (some 4,800 ft) took place under the Raritan River and adjacent marshland…

Read more of the article at http://www.undergroundsolutions.com/articles/TT-2010-Project-of-the-Year%20Winner.pdf

Underground Solutions provides infrastructure technologies for water and sewer applications. UGSI's Fusible PVC® products contain a proprietary PVC formulation that, when combined with UGSI's patented fusion process, results in a monolithic, fully-restrained, gasket-free, leak-free piping system. Fusible C-900® and Fusible C-905® both comply with AWWA C900 and C905 respectively and are certified to NSF 61.

Monday, November 8, 2010

Thursday, July 15, 2010

6,400 LF Pull of 16” FPVC® Pipe by Beaufort Jasper Water & Sewer Authority and Mears Group Extends Fusible PVC™ HDD Record

Less than three years after the record-setting 5,120 LF Secession Effluent Main project was successfully completed, Beaufort Jasper Water & Sewer Authority (BJWSA), Mears Group, Inc., and Underground Solutions, Inc. (UGSI) have set a new record for the longest single continuous horizontal directional drill (HDD) pullback of thermoplastic pipe.

In September 2008, BJWSA assumed ownership, operation, and maintenance responsibility for the water and wastewater systems at several local military facilities, including the Marine Corps Recruit Depot at Parris Island, SC. As part of the merger, all of the water and sewer utilities are undergoing upgrades and improvements. Due to restrictive Beaufort River discharge requirements, the military wastewater plants at the Air Station and Parris Island will be eliminated with flows diverted to the state-of-the-art Port Royal Island, SC Water Reclamation Facility.

Project: Military Wastewater Consolidation Project

Owner: Beaufort Jasper Water & Sewer Authority

Engineer: Hussey, Gay, Bell & DeYoung (HGBD)

Contractor: Mears Group, Inc.

Location: Beaufort, SC

Length: 6,400 LF

Pipe Size: 16” DR18 FPVC®

Pressure Test: 150 psi for 4 hours

UGSI Contact: Gary Shepherd; gshepherd@undergroundsolutions.com

The new sewer force main from Parris Island was installed under Archer’s Creek and the surrounding marsh via HDD to ensure minimal impact to the environment. Mears Group mobilized in October 2009 with two drill rigs, prepared to use the intersect method to complete the pilot drill if necessary. Ultimately, the 6,400 LF pilot drill exited on target without requiring the use of intersect technology. The bore hole was reamed out in three passes to a 32” diameter, then prepared by swabbing with a barrel reamer to clear cuttings and reinject clean slurry.

On December 2, 2009, the 6,400 length of fused 16” DR 18 FPVC® pipe was positioned on rollers and pulled into place with an excavator. The pull head was then connected to the drill stem to begin the process of pulling the pipe from Horse Island, under Archer’s Creek, and onto Jericho Island. The pipe emerged during the predawn hours of December 3rd to the applause of the small group of interested bystanders and a much larger number of tired, but satisfied workers.

Ed Saxon, BJWSA Deputy General Manager, commented: “The force main leaving Parris Island became a real design challenge because the narrow causeway linking the mainland was off limits to construction. Open cutting across the salt marsh would also have been very difficult, even had it been possible to permit. BJWSA’s growing body of experience with long HDD installations and recent advances in the technology made drilling the only viable option. Fusible PVC™ pipe was the only practical alternative for us, and we’ve had great experience with Mears Group as well.”

Ed Saxon, BJWSA Deputy General Manager, commented: “The force main leaving Parris Island became a real design challenge because the narrow causeway linking the mainland was off limits to construction. Open cutting across the salt marsh would also have been very difficult, even had it been possible to permit. BJWSA’s growing body of experience with long HDD installations and recent advances in the technology made drilling the only viable option. Fusible PVC™ pipe was the only practical alternative for us, and we’ve had great experience with Mears Group as well.”

Jennifer Oetgen with HGBD remarked: “The design was critical to a successful outcome; early onsite consultations with representatives from Mears and UGSI confirmed the viability of a 6,400 LF HDD, but the possibility of an intersect drill, staging that length of pipe, and working within the requirements of the military made this project particularly challenging and satisfying.”

In September 2008, BJWSA assumed ownership, operation, and maintenance responsibility for the water and wastewater systems at several local military facilities, including the Marine Corps Recruit Depot at Parris Island, SC. As part of the merger, all of the water and sewer utilities are undergoing upgrades and improvements. Due to restrictive Beaufort River discharge requirements, the military wastewater plants at the Air Station and Parris Island will be eliminated with flows diverted to the state-of-the-art Port Royal Island, SC Water Reclamation Facility.

Project: Military Wastewater Consolidation Project

Owner: Beaufort Jasper Water & Sewer Authority

Engineer: Hussey, Gay, Bell & DeYoung (HGBD)

Contractor: Mears Group, Inc.

Location: Beaufort, SC

Length: 6,400 LF

Pipe Size: 16” DR18 FPVC®

Pressure Test: 150 psi for 4 hours

UGSI Contact: Gary Shepherd; gshepherd@undergroundsolutions.com

The new sewer force main from Parris Island was installed under Archer’s Creek and the surrounding marsh via HDD to ensure minimal impact to the environment. Mears Group mobilized in October 2009 with two drill rigs, prepared to use the intersect method to complete the pilot drill if necessary. Ultimately, the 6,400 LF pilot drill exited on target without requiring the use of intersect technology. The bore hole was reamed out in three passes to a 32” diameter, then prepared by swabbing with a barrel reamer to clear cuttings and reinject clean slurry.

On December 2, 2009, the 6,400 length of fused 16” DR 18 FPVC® pipe was positioned on rollers and pulled into place with an excavator. The pull head was then connected to the drill stem to begin the process of pulling the pipe from Horse Island, under Archer’s Creek, and onto Jericho Island. The pipe emerged during the predawn hours of December 3rd to the applause of the small group of interested bystanders and a much larger number of tired, but satisfied workers.

Ed Saxon, BJWSA Deputy General Manager, commented: “The force main leaving Parris Island became a real design challenge because the narrow causeway linking the mainland was off limits to construction. Open cutting across the salt marsh would also have been very difficult, even had it been possible to permit. BJWSA’s growing body of experience with long HDD installations and recent advances in the technology made drilling the only viable option. Fusible PVC™ pipe was the only practical alternative for us, and we’ve had great experience with Mears Group as well.”

Ed Saxon, BJWSA Deputy General Manager, commented: “The force main leaving Parris Island became a real design challenge because the narrow causeway linking the mainland was off limits to construction. Open cutting across the salt marsh would also have been very difficult, even had it been possible to permit. BJWSA’s growing body of experience with long HDD installations and recent advances in the technology made drilling the only viable option. Fusible PVC™ pipe was the only practical alternative for us, and we’ve had great experience with Mears Group as well.”Jennifer Oetgen with HGBD remarked: “The design was critical to a successful outcome; early onsite consultations with representatives from Mears and UGSI confirmed the viability of a 6,400 LF HDD, but the possibility of an intersect drill, staging that length of pipe, and working within the requirements of the military made this project particularly challenging and satisfying.”

Thursday, May 20, 2010

New Fusible PVC Flow Calculator

Check out UGSI's new pipe flow calculator at the link below. This tool can be used to find head loss, pressure change, fluid velocity, and pumping costs for a variety of pipeline materials.

Check out UGSI's new pipe flow calculator at the link below. This tool can be used to find head loss, pressure change, fluid velocity, and pumping costs for a variety of pipeline materials.http://undergroundsolutions.com/pipe-flow-calculator.php

Tuesday, February 9, 2010

South Dakota Fusible PVC Project Sets a Record

In August 2009, King Contracting, Lincoln, Neb., completed a record-breaking horizontal directional drill (HDD) of 4,800 lin ft of 24-in. fusible polyvinyl chloride (PVC) pipe under Lake Oahe near Wakpala, S.D. The HDD crossing was part of an 80-mi raw water transmission pipeline being constructed by the Standing Rock Rural Water Sioux Indian Tribe.

In August 2009, King Contracting, Lincoln, Neb., completed a record-breaking horizontal directional drill (HDD) of 4,800 lin ft of 24-in. fusible polyvinyl chloride (PVC) pipe under Lake Oahe near Wakpala, S.D. The HDD crossing was part of an 80-mi raw water transmission pipeline being constructed by the Standing Rock Rural Water Sioux Indian Tribe.Crossing Lake Oahe was one of the most challenging aspects of constructing the new transmission line because of the lake's length and depth. The original design called for a 3,660-lin ft HDD installation beneath one of the lake's major tributaries. With a depth of nearly 100 ft, the design required 24-in. fusiblbe PVC pipe...

Thursday, January 28, 2010

Project Features Pipe Bursting with Fusible PVC™ Pipe System

"The massive Interstate 80 project to replace bridges and rebuild interchanges and roadway along this major east-west corridor has prompted other utility improvements along the way.

"The massive Interstate 80 project to replace bridges and rebuild interchanges and roadway along this major east-west corridor has prompted other utility improvements along the way.One of these—in South Salt Lake, Utah—involved replacement of an aging 18-inch asbestos-cement water transmission line beneath Roberts Avenue. As part of the Utah Department of Transportation’s State Street to 13th East Utility relocation project, the line was one of several water utilities targeted for upgrading due to potential settlement during the road project.

Pipe bursting was selected as the pipe replacement technology by the city and the engineering consultant, Horrocks Engineers (Pleasant Grove, Utah). The reasons were quick installation and the tightness of the site, and because asbestos-cement pipe can be problematic if excavated and removed. Pipe bursting would simply force the pipe fragments into the surrounding soil.

Pipe bursting was selected as the pipe replacement technology by the city and the engineering consultant, Horrocks Engineers (Pleasant Grove, Utah). The reasons were quick installation and the tightness of the site, and because asbestos-cement pipe can be problematic if excavated and removed. Pipe bursting would simply force the pipe fragments into the surrounding soil.

Fusible PVC pipe was chosen for the replacement pipe because of its reduced material costs..."

Subscribe to:

Comments (Atom)