Home to 90,000 residents and the University of Kansas, the City of Lawrence has been providing drinking water to the city and its surrounding areas for over 100 years. The city currently has two water treatment plants (Kaw WTP and Clinton WTP), six storage sites, 19 high service pumps, and a distribution system consisting of approximately 460 miles of pipe ranging in size from 2-inch to 24-inch that serves an area of 30 square miles.

The KAW Water Treatment Plant, originally built in 1917, is located on the south side of the Kansas River and draws water from the river and six alluvial wells. The treatment plant is well situated given that the majority of Lawrence is located south of the river, including the downtown area and the University of Kansas. The portion of the city located on the north side of the Kansas River (North Lawrence) received all of its treated drinking water via a single transmission line affixed to the Vermont Street bridges. The aging transmission main presented a major challenge to the City’s ability to provide reliable water service to North Lawrence.

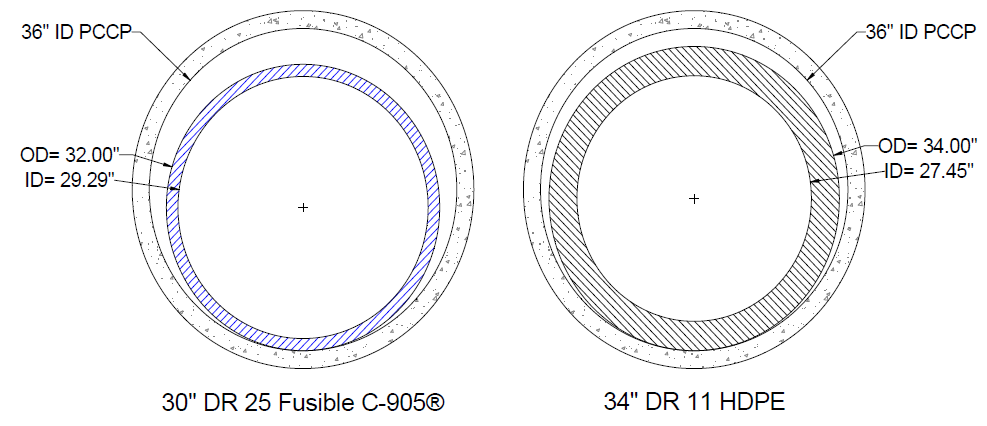

In order to provide another feed to North Lawrence, and provide additional supply for future growth, a second transmission main crossing the Kansas River was planned. Early in the preliminary design phase it was determined that horizontal directional drill (HDD) installation was the preferred method for crossing the Kansas River. An integral part of the preliminary engineering design included a material selection study. According to Jeff Heidrick of Burns and McDonnell, “The City of Lawrence liked the idea of installing a material that would not be susceptible to corrosion. Once it was demonstrated that Fusible PVC® pipe could meet the short-term installation stresses, long-term operating conditions, and was cost competitive with other options, it was selected as the preferred material.” Not only was Fusible PVC® pipe utilized in the HDD sections, it was also used in the open-cut sections to provide a fully-restrained pipe system for this critical section of infrastructure.

The project was competitively bid in December 2013. Garney Construction was the selected bidder and was awarded the project. Garney had completed multiple projects utilizing Fusible PVC® pipe, including the O’Connell Road Water Line Project in Lawrence that consisted of 9,400 LF of 16-inch and 800 LF of 12-inch Fusible PVC® pipe.

Garney subcontracted Environmental Crossings, Inc. (ECI) to perform the directional drills on the project. ECI mobilized to the job in March 2014 to start on the Kansas River drill. The alignment consisted of drilling through sandy clays with some gravels in the upper elevations and sandstone rock at the deeper elevations of the river crossing. While drilling sandstone can be time consuming and hard on down-hole drill equipment, it provides a stable borehole for pullback. The 2,400 LF Kansas River drill was pulled in over an 18-hour period on May 22, 2014. After the remaining two drill sections were installed, Garney began the open-cut portion of the job.

In total, 6,800 feet of 36-inch DR21 Fusible C-905® pipe was installed on the project, including three HDDs (2,400 LF, 1,400 LF, and 800 LF), 2,000 LF of open-cut, and approximately 200 LF of pipe installed inside a steel casing. The entire line was pressure tested and brought into service in January 2015, providing the City of Lawrence much needed redundancy and additional capacity within its system.